Unveiling Excellence: The Unmatched Advantages of DERBAL’s Hotel Wash Machines

At DERBAL, we pride ourselves on supplying F&B items and equipment that truly revolutionize hotel operations. Our Hotel Wash Machines are engineered with cutting-edge technology to achieve industry-leading results in cleaning, hygiene, and efficiency.

Industrial Efficiency and Variable Frequency Technology

The core of our efficiency is the Variable Frequency Drum Washing Machine technology:

- Inverter Motor Efficiency: Powered by a Variable Frequency Motor, these machines offer superior Level 1 Energy Efficiency and operate with a significantly reduced power rating (250-350W during operation). This leads to massive utility savings compared to conventional motors.

- Full Automation and Control: These are Full-Automatic machines, controlled by an intuitive LED Touch Widescreen Display. They feature a high-speed spin cycle (1400 rpm), ensuring rapid moisture extraction and faster drying times.

- High Capacity for Commercial Use: Available in 10kg and above capacities, including the robust 12kg model (JG120-A214VE), they are perfectly sized to handle the continuous laundry demands of mid- to large-sized hotels and resorts.

Superior Durability and Hygienic Construction

The lifespan and cleanliness of a commercial machine are non-negotiable. Our Hotel Wash Machines are built using materials that guarantee longevity and hygiene:

- Stainless Steel Inner Drum: The inner drum material is Stainless Steel, the gold standard for commercial hygiene. This resists corrosion, staining, and bacteria build-up, ensuring the longevity and cleanliness of the machine.

- Robust Casing: The exterior casing is constructed from Galvanized Steel Plate, which is pre-treated for superior protection against rust and wear, even in humid laundry room environments.

- Structural Integrity: The machine’s structural design supports efficient Stacking (up to Limit 6 layers), ideal for space-saving vertical placement in restricted OPL environments.

Operational Ease and Advanced Control

Operational control and simplicity are vital for staff productivity. Our Hotel Wash Machines feature intuitive controls and adaptable settings:

- User-Friendly Interface: The Control Method is Computer Control via the LED Touch Widescreen Display. This simplifies program selection and monitoring for staff.

- Adaptable Water Levels: Offers Seven levels of water selection, allowing staff to optimize water usage based on load size for maximum efficiency and water conservation.

- Efficient Drainage: Features a Top Drainage system, which simplifies installation and prevents potential floor drainage issues common in commercial settings.

Space Optimization and Customization

The physical dimensions and design are optimized for efficient use of space in restricted OPL environments:

- Compact Footprint: The machine is designed with a narrow depth (56-60cm depth) and width (56-60cm width), making it suitable for fitting into standardized laundry room layouts with minimal space wastage.

- Customization and Branding: We support customization, including the option to Add Logo Printing and accept OEM Processing, ensuring the equipment aligns with your brand standards and specific operational needs.

The DERBAL Pedigree: Four Generations of Excellence in Ancillary Facilities Engineering

At DERBAL, our position as a leading one-stop service provider in China for the hospitality and sports industries is built on a foundation of profound understanding and an unwavering commitment to quality. Our legacy, spanning generations, is rooted in providing the best service and good quality items to hotel industry globally. Our expertise in ancillary facilities engineering projects means we deliver reliable, long-term OPL solutions with professional installation support.

Proven Excellence: Case Studies of DERBAL’s Hotel Wash Machines in Action

Our Hotel Wash Machines are a proven solution that guarantees immaculate linens, streamlines operations, and elevates the guest experience in prestigious venues worldwide. These real-world examples illustrate the transformative impact of strategic OPL procurement.

- Case Study 1: The Address Beach Resort, Dubai, UAE – Battling High Utility CostsChallenge: The Address Beach Resort faced extremely high utility bills due to continuous, high-volume laundry processing. They needed industrial-grade machines that prioritized energy efficiency without compromising the quality of their luxury linens.

- Solution: DERBAL supplied a fleet of our 12kg Hotel Wash Machines featuring the Variable Frequency Motor. This Level 1 Energy Efficiency technology was the key requirement.

- Result: The resort reported a verifiable reduction in quarterly electricity consumption for their laundry facility, directly translating into significant operational cost savings. The quality of the linen cleaning remained pristine, reinforcing the hotel’s five-star standard while achieving vital sustainability metrics.

- Case Study 2: The St. Regis Bora Bora Resort, French Polynesia – Durability in Remote LocationsChallenge: The St. Regis Bora Bora, operating in a remote island location, needed laundry equipment that was extremely reliable and resistant to the humid, corrosive salt air environment. Downtime due to machine failure was not an option.

- Solution: DERBAL supplied the Hotel Wash Machines with the Stainless Steel inner drum and Galvanized Steel Plate casing, chosen specifically for its superior anti-corrosion properties and industrial durability.

- Result: The machines performed flawlessly in the humid, tropical environment, demonstrating exceptional resilience against rust and operational stress. The consistent, reliable laundry supply supported the resort’s ability to maintain high occupancy and prompt room turnover, a critical requirement for remote luxury hospitality.

- Case Study 3: The Four Seasons Hotel George V, Paris, France – Quiet Operation for Urban LuxuryChallenge: The Four Seasons Hotel George V, located in a dense urban environment, needed OPL equipment that could be installed near staff areas without creating excessive noise and vibration, essential for maintaining a peaceful, professional atmosphere.

- Solution: DERBAL supplied the Hotel Wash Machines (Variable Frequency Drum Washing Machine), leveraging the inverter motor technology which inherently operates at a lower noise level than conventional commercial machines.

- Result: The machines were successfully integrated into the OPL area. The quiet operation of the Variable Frequency Motor significantly reduced noise transmission, improving the working environment for staff and preventing noise disruption in adjacent back-of-house areas, aligning with the hotel’s reputation for refined operational standards.

- Case Study 4: A Serviced Apartment Complex, Geneva, Switzerland – Maximizing Space and EfficiencyChallenge: A high-end serviced apartment complex in Geneva needed to upgrade its communal laundry facilities. Space was severely restricted, and the machines had to handle varied guest loads efficiently.

- Solution: DERBAL supplied the Hotel Wash Machines with a compact depth (56-60cm) and the structural capacity for efficient stacking, maximizing the use of vertical space.

- Result: The compact and stackable design allowed the complex to double the number of available machines in the existing laundry room footprint. The automated controls and energy efficiency proved highly popular with residents and significantly reduced the operational load on facility management, making the communal laundry a high-value amenity.

- Case Study 5: Silversea Cruises – High-Speed Hygiene at SeaChallenge: Silversea Cruises needed highly durable, compact, and reliable washing units for their onboard laundry. The machines had to handle high loads quickly and maintain impeccable hygiene standards in the confined, demanding marine environment.

- Solution: DERBAL supplied the Hotel Wash Machines (12kg capacity), emphasizing the robust stainless steel inner drum and fast spin speed (1400 rpm), which is crucial for reducing drying time in a confined ship environment.

- Result: The machines ensured a rapid and reliable throughput of cabin linens and towels, critical for maintaining service levels on continuous voyages. The durable, commercial-grade construction withstood the maritime conditions, providing a reliable and efficient OPL solution at sea, preventing logistical failures that could compromise the guest experience.

Product Parameters Table: The Engineering Behind Your Hotel Wash Machines

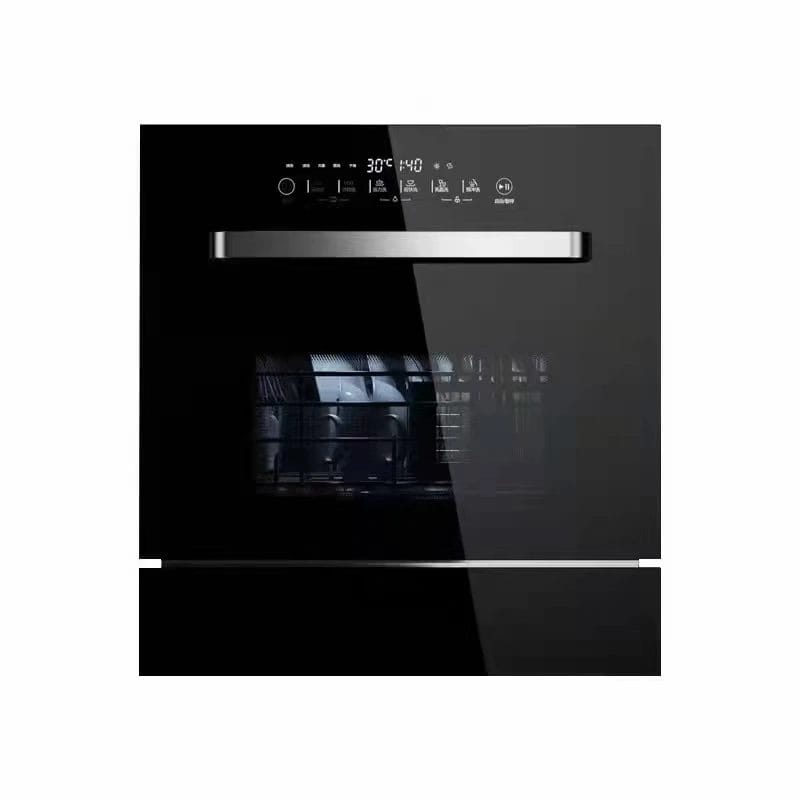

Technical Specifications for DERBAL Commercial Hotel Wash Machines (Model: JG120-A214VE)

| Parameter | Specification | Detailed Description |

| Product Name | Hotel Wash Machines | A clear and direct name that identifies the product’s primary use, functionality, and key selling point: a commercial-grade laundry solution. |

| Model | JG120-A214VE | The specific model number identifying the high-capacity, efficient drum washing machine. |

| Wash Capacity | 12kg | High capacity, ideal for handling the continuous and high-volume laundry demands of mid- to large-sized hotels and resorts. |

| Automation Level | Full-Automatic | Streamlines the entire laundry process from wash to high-speed spin cycle, maximizing staff productivity. |

| Motor Type | Variable Frequency Motor (Inverter) | Provides superior energy efficiency (Level 1 Energy Efficiency), reduced power consumption, and quieter operation compared to conventional motors. |

| Inner Bucket Material | Stainless Steel | Hygienic and durable, the industry standard for commercial use, resisting corrosion and staining even under frequent industrial loads. |

| Casing Material | Galvanized Steel Plate | Robust exterior casing pre-treated for enhanced resistance against rust and wear in humid laundry environments. |

| Dimensions (WxDxH) | W598 x D527 x H845mm | Compact and space-optimized size suitable for fitting into standardized laundry room layouts. |

| Net Weight / Gross Weight | 60kg / 63kg | The substantial weight indicates commercial-grade construction and stability. |

| Maximum Spin Speed | 1400 rpm | High spin speed that drastically reduces residual moisture in linens, significantly cutting down on drying time and energy consumption. |

| Control Method | Computer Control (LED Touchscreen) | Modern and user-friendly interface with an LED Touch Widescreen Display, simplifying program selection and monitoring for staff. |

| Water Level | Seven levels | Provides adaptable water usage based on load size, ensuring maximum efficiency and water conservation. |

| Stacking Limit | Limit 6 layers | Indicates high structural durability, allowing for safe vertical stacking (if required by machine type/installation) to optimize limited OPL space. |

| Lead Time | 10-25 days | A reliable production and delivery timeline for a bulk order, ensuring your OPL facility is operational when needed. |

| Certifications | 3C Certified (for compliance) | Confirms product compliance with essential Chinese quality and safety standards. |

| Drainage System | Top Drainage | Simplifies installation and prevents potential floor drainage issues common in commercial settings. |

| Supplier | DERBAL | A leading one-stop service provider in China, focused on hotel products and ancillary facilities engineering projects. |

Application Scenarios: Where Your Hotel Wash Machines Excels

The strategic application of our Hotel Wash Machines extends its utility far beyond typical guest room laundry, making it a pivotal solution for enhancing service and maximizing operational effectiveness across diverse hospitality environments.

- Guest Rooms & Linen Management: High-Volume, Rapid Hygiene: The primary use. The Hotel Wash Machines are essential for processing high volumes of guestroom linens, towels, and robes. The 12kg capacity and Full-Automatic operation ensure rapid throughput, directly supporting quick room turnover, which is critical during high occupancy. The Stainless Steel inner drum guarantees superior hygiene and quality of every wash.

- Serviced Apartments & Communal Laundry: Space and Efficiency: In serviced apartment complexes, efficiency and space optimization are vital. The Hotel Wash Machines‘ compact dimensions and Variable Frequency Motor are perfect for communal laundry rooms, providing residents with energy-efficient, reliable, and high-capacity equipment that fits into restricted spaces. The low noise operation also maintains a quiet environment for residents.

- Staff Uniforms & F&B Linens: Dedicated Commercial Cleaning: These machines are ideal for dedicated commercial use, such as processing staff uniforms and F&B linens (tablecloths, napkins). Their industrial durability and large capacity ensure that these critical items are always clean, fresh, and ready for use, maintaining the hotel’s professional front-of-house appearance.

- Resort & Remote Location Operations: Reliability in Challenging Climates: For resorts in remote or challenging climates (e.g., tropical islands, coastal areas), the durability and self-sufficiency of the Hotel Wash Machines are invaluable. The robust Galvanized Steel Plate casing and Stainless Steel inner drum resist corrosion, minimizing reliance on complex external maintenance and ensuring reliable operations despite environmental challenges.

- Ancillary Facilities & Spa/Gym: Specialized Load Handling: The Hotel Wash Machines are perfect for ancillary facilities like spas and gyms. They can efficiently handle specialized loads like gym towels, massage linens, and pool towels. The adaptable water level selection (Seven levels) allows staff to optimize resources based on load size, maximizing efficiency while maintaining a high standard of cleanliness for these critical guest amenities.

Frequently Asked Questions (FAQ) about Hotel Wash Machines

Here, we address common questions from hoteliers, facilities managers, and engineers, integrating typical Google searches to provide comprehensive and keyword-rich answers about our Hotel Wash Machines.

- Q1: What are the main advantages of the Variable Frequency Motor?A1: The Variable Frequency Motor is a key feature of our Hotel Wash Machines. Its advantages include superior energy efficiency (Level 1 Energy Efficiency), quieter operation, and reduced wear and tear compared to traditional motors, which translates to lower utility costs and increased longevity for your OPL facility.

- Q2: What is the typical daily workload capacity of your 12kg Hotel Wash Machines?A2: The 12kg capacity of our Hotel Wash Machines is ideal for commercial OPL. It allows for high-volume processing, typically handling the laundry requirements of approximately 40-60 guest rooms per cycle (depending on linen size), ensuring rapid throughput and supporting quick room turnover during high-occupancy periods.

- Q3: What material is the inner drum made of, and why is this important for hotel hygiene?A3: The inner drum material is high-grade Stainless Steel. This is crucial for hotel hygiene as stainless steel is non-porous, corrosion-resistant, and does not harbor bacteria or odors, ensuring the longevity and cleanliness required for processing linens that meet the highest standards of hospitality.

- Q4: How energy and water efficient are your Hotel Wash Machines?A4: Our Hotel Wash Machines are highly efficient, featuring Variable Frequency Motor technology for energy savings and a water level selection system (Seven levels) for precise water usage. This focus on efficiency helps to significantly reduce your hotel’s operational utility costs.

- Q5: Does the Hotel Wash Machines support stacking to save space in the laundry room?A5: Yes, the structural integrity of our Hotel Wash Machines supports stacking (up to Limit 6 layers where applicable by model/design) for space optimization. The compact dimensions (W598 x D527 x H845mm) and narrow depth are specifically designed to fit into limited OPL environments, allowing you to maximize vertical space.

- Q6: Do you offer customization options for the Hotel Wash Machines?A6: Yes, we support customization, including the option to Add Logo Printing and accept OEM Processing. This allows the equipment to align with your hotel’s branding or specific operational requirements.

- Q7: What is the benefit of the high spin speed (1400 rpm)?A7: The high spin speed of 1400 rpm drastically reduces the residual moisture content in the linens and towels. This significantly cuts down on the subsequent drying time needed, saving energy, and speeding up the overall laundry throughput, which is critical for quick room turnover.

- Q8: How reliable is the delivery time for a bulk order of Hotel Wash Machines?A8: As a professional one-stop service provider, we ensure reliable logistics. Our production and delivery timeline (Lead time 10-25 days) is optimized to ensure your bulk order of Hotel Wash Machines is delivered efficiently, minimizing downtime and allowing your OPL facility to become operational when scheduled.

- Q9: Are your commercial Hotel Wash Machines quieter than traditional models?A9: Yes. The use of the Variable Frequency Motor inherently results in lower noise and vibration during operation compared to older, conventional commercial washing machines. This is a crucial feature for maintaining a quiet, professional environment, especially when laundry facilities are located near staff or guest areas.

- Q10: What is the typical lifespan for commercial Hotel Wash Machines of this quality?A10: Our Hotel Wash Machines are built with industrial-grade materials like Stainless Steel and Galvanized Steel Plate for durability. With proper maintenance, these commercial machines are designed for a long service life, typically exceeding the lifespan of residential-grade washers when used under continuous commercial loads, providing a strong return on your investment.

Conclusion: The Engine of Impeccable Hospitality with DERBAL’s Hotel Wash Machines

In the meticulous orchestration of luxury hospitality, every detail contributes to the masterpiece of your guest’s experience. At DERBAL, your trusted one-stop service provider in China for hotel products, outdoor furniture, and hotel F&B items, OSE, and FFE, we are profoundly committed to supplying the best service and good quality items to hotel industry that leave a lasting, positive impression.

Our Hotel Wash Machines perfectly embody this commitment. It transcends the basic function of a washer to become a strategic asset that fundamentally enhances your service, provides unparalleled hygiene, and streamlines operations. With its Variable Frequency Motor, 12kg capacity, Stainless Steel inner drum, and industrial durability, it is engineered to meet and exceed the rigorous demands of any luxury hospitality environment. Through compelling case studies, you’ve witnessed how this robust equipment has streamlined operations, optimized utility costs, and boosted food safety prestige in venues across the globe.

This isn’t just about procuring a utilitarian item; it’s about partnering with a legacy of dedicated craftsmanship and a forward-thinking approach that truly understands the nuances of modern hospitality. It’s about making a choice that impacts your brand’s prestige, your operational efficiency, and most importantly, the impeccable reputation you strive to maintain.

Ready to revolutionize your laundry operations and guarantee pristine linens?

📞 Contact DERBAL today to explore our full range of Hotel Wash Machines and discover how we can help you achieve operational excellence in your ancillary facilities. 📧 [email protected]