High-frequency service lives and dies on the smallest details. Sauce bowls seem minor until rim chips, glaze wear, and poor stackability slow the line and dilute guest perception. This Restaurant Sourcing Guide focuses on wholesale procurement for restaurants, hotels, and large resorts—prioritizing durability, replenishment speed, and total landed cost efficiency.

Key takeaways

-

Specify fully vitrified porcelain with alumina reinforcement, plus proof: ASTM C368 rim-impact values, EN 12875 dishwasher endurance, thermal shock evaluations, and glaze abrasion/metal-marking protocols.

-

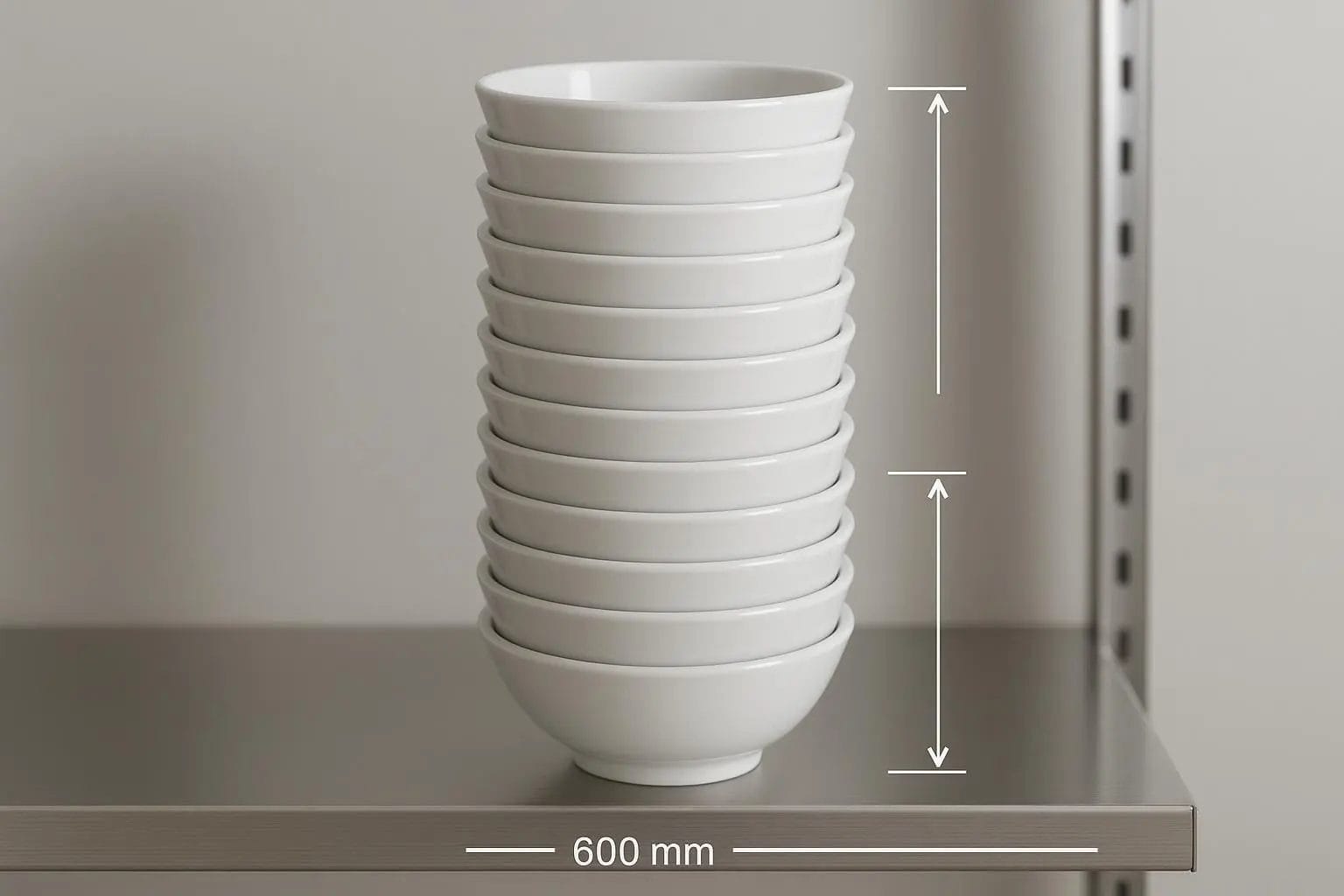

Standardize capacities (1.5–2 oz individual, 3–4 oz shared) and require measurable stackability metrics (e.g., stack height per 12/24) to speed service and simplify inventory.

-

Demand food-contact compliance: EU 84/500/EEC (lead/cadmium), FDA action level alignment, and LFGB where applicable—especially for decorated/printed bowls.

-

Reduce landed cost with Tariff-Optimized Logistics: correct HS code selection, compliant duty engineering on viable trade lanes, and clear Incoterms.

-

Use a procurement workflow: samples → in-kitchen trials → lab tests → acceptance thresholds in the PO → production with QA and protective packaging.

Dipping Sauce Bowls and Small Sauce Bowls

Dipping Sauce Bowls and Small Sauce Bowls play a quiet but decisive role in guest experience and throughput. Consistent condiment portions reduce waste and keep plating tight, which matters during peak hours when each second compounds across hundreds of covers.

Operationally, the winning range for most commercial programs is 2–4 oz with shallow or gently flared walls. Shallow dishes make it easier for guests to access viscous sauces and reduce tipping on crowded trays. In buffet or banquet service, specify a variant with a wider base for stability on chafing stands and pass trays. For à la carte outlets, pair a 2 oz shallow dish for single-guest condiments with a 3–4 oz option for shareable items. Standardizing this small family cuts SKU complexity and accelerates replenishment.

Mini-case (banquet operations): A 900-room conference hotel replaced mixed, non-vitrified dipping bowls with fully vitrified porcelain units and standardized to two capacities. By switching to a rounded, reinforced rim, they reduced rim-chip incidents logged by stewarding by an estimated 28% over a quarter, while plating teams reported fewer re-plates from micro-cracks and better stacking on speed racks. The change streamlined ordering as well—one approved SKU reorders faster than four lookalikes.

Commercial Dipping Dishes and Durable Ceramic Sauce Dish

Commercial Dipping Dishes must endure relentless cycles. A Durable Ceramic Sauce Dish program should center on fully vitrified porcelain with alumina content. Vitrification creates a dense, low-absorption body that resists microfractures; alumina promotes mullite formation that correlates with improved edge strength. Ask suppliers to declare water absorption (target ≤0.5%) and body formulation basics.

Durability and verification—what to request and why:

-

Impact and rim-chip resistance: Request third-party lab reports for ASTM C368 showing the energy at first chip and at complete failure, with sample sizes and failure modes. This method evaluates rim impacts similar to the knocks bowls experience in stewarding and on the pass. See the standard overview in the ASTM C368 impact resistance method description and this plain-language context from the ANSI explainer on tableware safety standards.

-

Dishwasher endurance: Reference EN 12875 series for mechanical dishwashing resistance and ask for explicit cycle counts (e.g., 125–250 standard or accelerated equivalents) with pass/fail visual criteria. A concise method summary is available via EN 12875 overview resources and standard abstracts such as EN 12875-2 inspection protocol.

-

Thermal shock tolerance: When claiming microwave/oven suitability, request thermal shock test reports using adapted methods (e.g., ASTM C484 or ISO/EN 10545-9 proxies) with declared ΔT ranges and pass criteria. See Intertek’s ASTM C484 method summary.

-

Glaze abrasion and metal marking: In the absence of a dinnerware-only abrasion standard, ask for ISO 10545-7-style results or Taber Abrasion indices, and a documented metal-marking protocol. Technical literature illustrates how glaze composition affects metal marking; see Hennetier et al. on porcelain metal marking behavior.

-

Food-contact safety: Require migration tests for lead and cadmium per EU rules and FDA action levels, including tests on decorated surfaces. Refer to the EU’s consolidated 84/500/EEC directive and the FDA’s guidance page on lead in food and foodwares.

What to put in your RFQ/PO acceptance criteria:

-

ASTM C368 rim-impact minimums (negotiate joules suitable for banquet vs. à la carte)

-

EN 12875 cycle targets with “no crazing/no visible glaze degradation” criteria

-

Thermal shock ΔT and cycles for any oven/microwave claims

-

Glaze abrasion/metal-marking protocol with acceptable rating

-

EU and FDA migration reports; LFGB where applicable; declarations for decals

Stackable Sauce Bowls

Stackable Sauce Bowls are a non-negotiable in high-frequency operations. Two geometry details matter most: a stable, slightly rolled rim that resists micro-chipping and a precise foot ring that nests without wedging. During sampling, physically measure a 12-count stack and record total stack height and average added height per bowl; confirm stability under light vibration to simulate speed-rack movement.

Practical spec language you can use: “Per model, declare nest count per stack (12/24), total stack height tolerance (±3 mm), and 0% wedging rate in standard handling. Foot-ring and contact-point glazing to minimize sticking. Confirm compatibility with standard dish racks.” These small lines save minutes per service which, across a resort complex, add up to hours per week.

Custom Logo Sauce Bowls and Bulk Order

Custom Logo Sauce Bowls elevate brand presence while helping guests identify condiments at a glance. For durability, specify decal type (in-glaze, on-glaze, underglaze), color references, placement, and the post-decoration test plan. Insist that migration testing be repeated on the decorated surface and that dishwasher cycles per EN 12875 are re-validated with the logo applied.

A robust Bulk Order workflow for hospitality buyers looks like this:

-

Samples: Request two capacities (2 oz and 3–4 oz), plus undecorated and decorated versions.

-

In-kitchen trial: Run for at least two high-volume service days. Record chips, metal marking, and any wedging/sticking.

-

Lab validation: Commission ASTM C368 rim-impact, EN 12875 dishwasher endurance, thermal shock proxies with defined ΔT, and glaze abrasion/metal-marking checks.

-

Commercial terms: Lock in acceptance thresholds inside the PO. Add packaging requirements (edge protection, carton drop testing) to minimize breakage in transit.

-

Production & QA: Approve golden samples; retain them for inbound QC; document foot-ring tolerances and decal positioning.

Practical example — disclosure and process note: Disclosure: DERBAL is our product. In multi-outlet resorts, teams have used a neutral two-size bowl family with underglaze branding to standardize condiments across outlets while keeping breakage low. For operational questions like lead times or MOQ consolidation, see the DERBAL FAQ, and for QA transparency, review their site’s factory-tour materials via the main navigation.

Small Bowl for Sauce Called and Soy Sauce Bowl

Procurement teams often ask: what is the Small Bowl for Sauce Called in catalogs? The most common commercial descriptors are ramekin, dipping bowl/dipping dish, condiment cup, monkey dish, and Soy Sauce Bowl. While the terms overlap, their geometries drive use cases.

For Japanese and Fusion outlets, a Soy Sauce Bowl is typically a shallow dish, often 2.5–4 inches in diameter and under 1 inch deep, designed for soy, ponzu, chili oil, or wasabi mixing. Shallow dishes reduce splashing and over-pouring at the table and photograph cleanly on sushi/sashimi boards. Ramekins, by contrast, often have straighter walls and can be better for baked or heated sauces where depth matters.

Standardize a naming convention that procurement, culinary, and stewarding all use, and lock capacities by use case: 1.5–2 oz for individual settings; 3–4 oz for share plates; 5–6 oz for appetizer accompaniments. This vocabulary avoids substitution errors and speeds replenishment across outlets.

One-stop Hotel Solution and DERBAL

When you’re consolidating OS&E across a resort portfolio, the goal is a One-stop Hotel Solution that balances durability, brand consistency, and landed cost. Start with materials and testing (vitrified porcelain with alumina; ASTM C368, EN 12875, thermal shock proxies; glaze abrasion/metal-marking checks). Confirm food-contact compliance for EU and U.S. markets, including decorated pieces.

Then align logistics and tariffs. Confirm HS codes (porcelain/china tableware generally falls in HS 6911; other ceramics in HS 6912—final 10-digit codes depend on article specifics), and select Incoterms 2020 to match your capabilities. Authoritative primers like the U.S. Trade.gov guide to Incoterms clarify cost and risk splits. For international buyers, Tariff-Optimized Logistics means combining accurate classification with compliant duty engineering along viable trade lanes and clear Incoterms. Done correctly, that reduces total landed cost and shortens replenishment timelines.

If you prefer a single touchpoint, DERBAL supports consolidated OS&E sourcing alongside dinnerware programs. The brand’s emphasis on Tariff-Optimized Logistics helps buyers reduce total landed cost through correct classification and trade-lane planning while keeping MOQs and replenishment practical for multi-outlet properties. To scope a bulk quote or request a custom design for branded sauce bowls, contact DERBAL through the website and reference your required tests (ASTM C368, EN 12875) and stackability metrics.

Internal links for further reading on the DERBAL site: review operations answers in the FAQ and explore hotel deployment examples via the site’s Hotel Projects materials accessible from navigation.

Procurement checklist

-

Body and composition: fully vitrified porcelain with alumina; water absorption ≤0.5%; glaze fit statement.

-

Durability tests: ASTM C368 rim-impact (J at first chip/failure; sample sizes); EN 12875 dishwasher cycles with visual criteria; thermal shock ΔT/cycles via adapted methods; glaze abrasion & metal-marking protocol/results.

-

Food safety: EU 84/500/EEC migration report (lead/cadmium); FDA action-level alignment; LFGB where applicable; post-decoration tests on logos.

-

Operations: capacity standardization (1.5–2 oz, 3–4 oz, 5–6 oz); declared stack metrics (12/24 count, total stack height, 0% wedging); rack compatibility.

-

Logistics: proposed HS code (6911/6912), Incoterms (FOB/CIF/DDP) with risk/cost clarity; packaging specs and carton drop-testing; replenishment lead times; mixed-SKU palletization where allowed.

External references cited in context: ASTM C368 for impact resistance; EN 12875 series for dishwashing resistance; EU 84/500/EEC for lead/cadmium; FDA guidance on lead in foodwares; Incoterms explanations from Trade.gov. Keep your link density manageable and your acceptance thresholds explicit in the PO to avoid ambiguity at inbound QC.

FAQ: Wholesale Sauce Bowls & Dipping Dishes

1. What makes DERBAL sauce bowls “commercial grade” compared to retail options?

Commercial-grade bowls must withstand 100+ high-temperature dishwashing cycles daily and constant stacking. DERBAL sauce bowls are crafted from fully vitrified porcelain with alumina reinforcement, ensuring a water absorption rate of ≤0.5%. This process creates a dense body that resists micro-fractures, edge chipping, and glaze abrasion, which are common issues with standard retail ceramics.

2. How can I determine the right size sauce bowl for my restaurant or resort?

Standardization is key to reducing SKU complexity. We recommend three primary capacities based on operational data:

-

1.5–2 oz: Ideal for individual condiments like ketchup, butter, or mayo.

-

3–4 oz: Best for shared dipping sauces (e.g., soy sauce, chili oil) or small side appetizers.

-

5–6 oz: Designed for large appetizer accompaniments or soup starters.

3. Are your decorated or custom logo bowls safe for food contact?

Yes. At DERBAL, we prioritize food-contact compliance. Our decorated bowls undergo rigorous migration testing for lead and cadmium, aligning with EU 84/500/EEC and FDA action levels. We recommend re-validating dishwasher endurance (EN 12875) specifically for decorated surfaces to ensure the logo remains vibrant over time.

Optimize Your OS&E Procurement with DERBAL Experts Stop guessing on durability and logistics. Whether you are standardizing a multi-outlet resort or sourcing for a specific banquet project, DERBAL provides the technical validation (ASTM C368/EN 12875) and tariff-optimized logistics you need to reduce total landed cost. 👉 Get a Professional Technical Quote & Sample Kit