A quiet room can be undone by a faint, persistent hum. A beautiful cabinet can warp from trapped heat. I’ve seen both in newly opened suites that “checked every box” on the mood board—but missed two engineering basics: the right technology and the right ventilation. A hotel mini fridge isn’t just a convenience; it’s a comfort system, a warranty risk if installed poorly, and a line item that shows up in your five‑year TCO.

In our two decades of FF&E work, here’s the simple truth: the best guest room fridge is the one guests never notice, engineering can service without tearing out millwork, and procurement can defend in an RFP.

Key takeaways

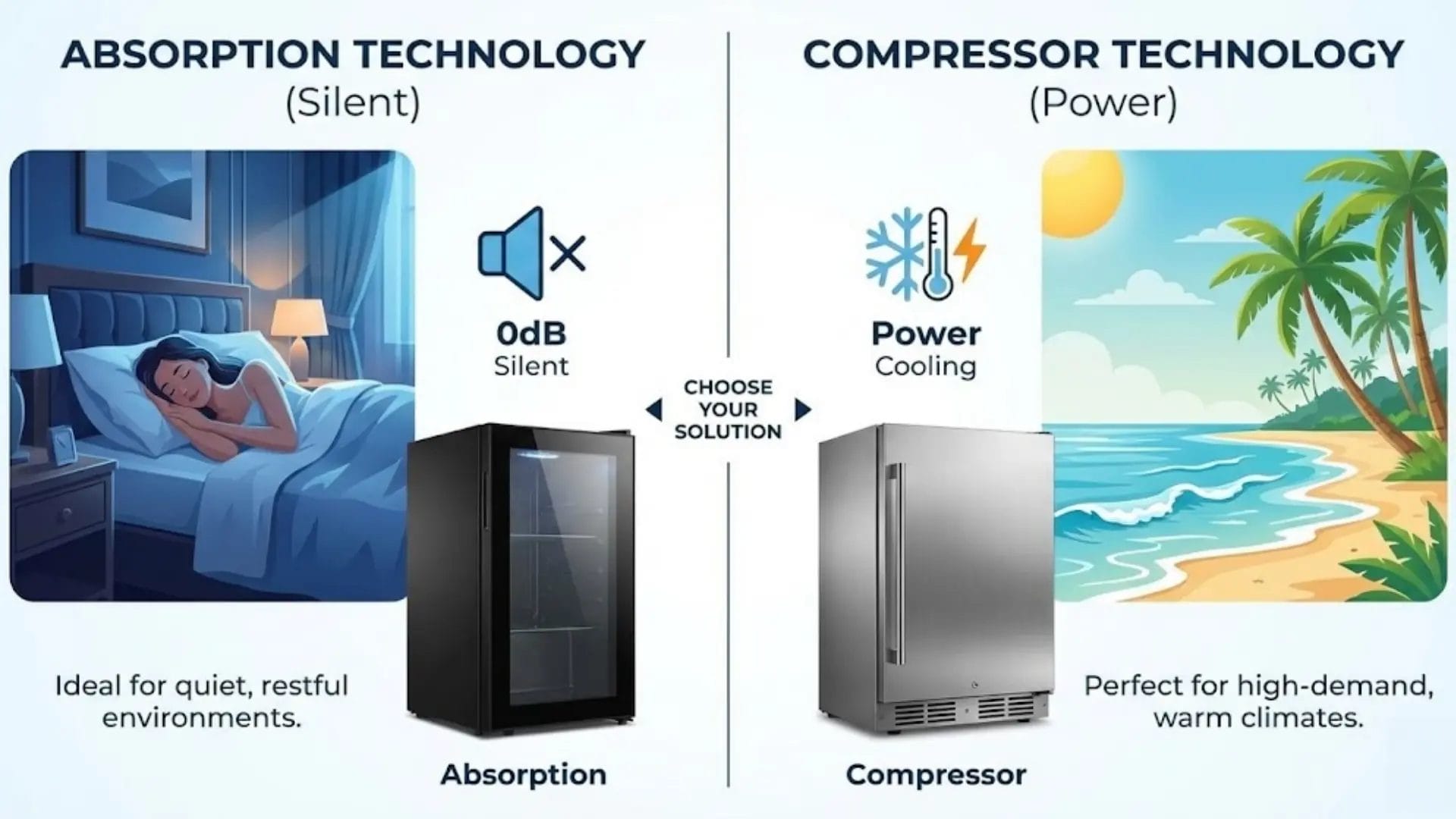

- Start with use case, not just looks: luxury suites often demand 0dB absorption; hot climates or rapid pull‑down favor compressors.

- The #1 killer is suffocation: plan built‑in airflow early and treat 200cm² per opening as a common manufacturer baseline (verify per model).

- Don’t chase the lowest sticker price: TCO swings on energy, ventilation quality, and lifespan—not just initial cost.

- Specify refrigerant and certifications up front: R600a is common for efficiency; treat Energy Star and EN 16825 as model‑specific.

- Millwork, hinges, and vent geometry must “speak the same language” during FF&E—get engineering sign‑off before fabrication.

Understanding the Tech: Absorption vs. Compressor Mini Fridges

Designers often ask why hotels don’t just buy standard “dorm fridges.” The answer boils down to two factors: acoustics and duty cycle. Unlike a home office, a hotel guestroom demands absolute silence at 2 AM and a cooling system that can withstand constant door-opening by travelers.

-

Absorption Systems: The “Silent King” For luxury suites where the guest’s sleep quality is non-negotiable, absorption technology is the gold standard. With no moving parts, no compressors, and no fans, a high-quality absorption minibar runs at a true 0dB. In our two decades of FF&E experience, we’ve found that high-end brands prioritize this “silent luxury” above all else. When installed with proper ventilation, these units provide a seamless, vibration-free experience that traditional cooling simply cannot match.

-

Compressor Systems: Built for Performance Compressor units are the workhorses of the industry, particularly for tropical resorts or high-turnover hotels. They pull down temperatures rapidly and maintain them even in humid, high-ambient conditions. However, the trade-off is sound. While hotel-grade compressor units are significantly quieter than residential models, they typically operate in the 28dB to 38dB range. This is why we often recommend compressor models for beachfront properties where the hum of the AC or the ocean provides a natural sound mask.

-

Thermoelectric (Peltier): The Niche Solution These solid-state units are lightweight and can be very quiet, but their cooling capacity is modest. In our view, they are best suited for specific cabinetry designs where depth is extremely tight and the climate is strictly controlled.

Pro Tip: Don’t just pick a fridge; pick a guest experience. According to guest satisfaction benchmarks from the National Association of Hotel & Lodging Engineers (NAHLE), ambient noise is a top-three factor in room complaints. For premium suites, choose Absorption. For high-performance cooling in warm climates, go with Compressor.

The #1 Killer of Hotel Mini Fridges: Improper Ventilation

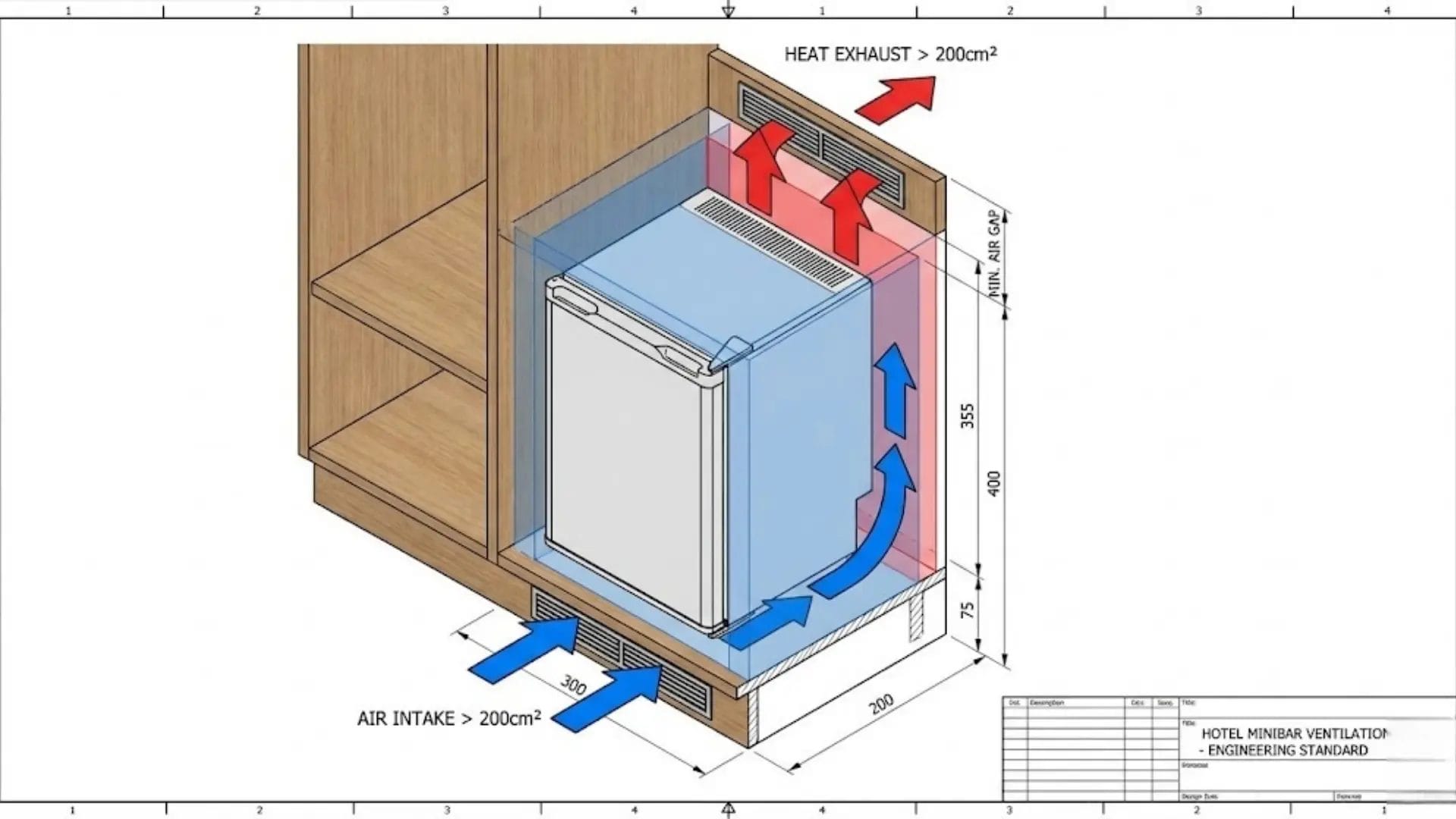

What many designers and procurement managers overlook is that built-in furniture changes the fundamental physics of cooling. A hotel mini fridge is essentially a heat-exchange engine; it rejects heat from the cabinet to the environment. If your joinery traps that heat, the interior temperature warms up, energy consumption spikes, and expensive components fail prematurely.

In our 20 years of FF&E experience, we call this “Cabinet Suffocation.”

The Engineering Standard: The “200 Rule”

Across the technical manuals of top-tier global manufacturers, a clear pattern emerges: to ensure a fridge lives its full lifespan, you must provide a free-area opening for air intake and another for exhaust, separated by a defined airflow path.

The industry-standard baseline is a minimum of 200 cm² (approximately 31 sq.in.) of free area for both the inlet and the outlet. Failing to meet this requirement often voids manufacturer warranties and leads to a cycle of constant guest complaints regarding “warm drinks.”

| Ventilation Quality | Internal Temp Stability | Energy Consumption | Lifespan |

| Proper (200 cm²+ / clear duct) | High & Steady | Optimized (Lower) | 6 – 8 Years |

| Poor (< 50 cm² / blocked) | High Fluctuations | Excessive (+35%) | 1 – 2 Years |

Three Airflow Patterns That Actually Work

To avoid “Cabinet Suffocation,” your furniture design must follow one of these three proven engineering paths:

-

The Chimney Path: Bottom-front intake (via a plinth/toe-kick) with a clear rear-top exhaust. This is the cleanest design for modern guestrooms; just ensure the rear “chimney” remains unobstructed.

-

The Vertical Duct: Rear-bottom intake with a dedicated vertical duct leading to a top exhaust. The key here is keeping the duct smooth—never allow preheated air to re-circulate back into the intake.

-

The Generous Plinth: A wide plinth intake with a vertical rise to a top louver. Because a narrow plinth limits the free area, the intake slot must be widened to meet the 200 cm² threshold.

Engineering Insight: > Energy efficiency isn’t just a buzzword—it’s a requirement for modern hospitality. According to the National Association of Hotel & Lodging Engineers (NAHLE), equipment that operates under thermal stress consumes significantly more power and has a higher failure rate. By prioritizing ventilation in your FF&E specs, you are directly contributing to your hotel’s ESG goals and long-term ROI.

Integration Design: Matching Aesthetics with Functionality

A guest room fridge can look bespoke and still breathe. The trick is aligning millwork, hinges, clearances, and airflow before fabrication.

Door systems and clearances

- Door‑on‑door hinges couple the cabinet door to the fridge door for a clean façade. Check maximum decor panel thickness/weight and swing clearance. Allow service access without removing the entire case.

- Sliding hinges can ease alignment in tight envelopes and tolerate slight panel shifts but demand precise reveals to avoid rubs.

- Reversible doors are helpful for mirrored room types; plan for handle swing and stops so the door doesn’t fight drapes or nightstands.

A practical micro‑workflow we lean on

- Confirm the ventilation path and free‑area targets from the chosen model’s manual (e.g., 200cm² per opening baseline, more if the vendor demands it).

- Size the toe‑kick and top louver using free‑area, not just nominal grill dimensions (mesh and blades reduce free area).

- Check hinge geometry against panel thickness and weight; mock the swing in CAD to catch countertop overhangs and pulls.

- Validate the installation envelope, including rear duct width and service access.

- Before millwork sign‑off, run a 24‑hour bench test in a prototype cabinet to log dB at 1 m and interior temperature stability after a simulated restock.

Where it helps, we reference model‑specific cabinet‑fit examples. For quiet‑operation casework, see this silent minibar page for typical cabinet integration specs: Silent luxury hotel mini bar fridge. For broader coordination or wholesale sourcing support, many FF&E teams keep a single engineering contact at DERBAL to review grille sizing, hinge compatibility, and service access during the FF&E phase.

An anonymized case in brief During a 180‑key coastal renovation, tightening the plinth intake, adding a rear chimney louver, and resetting the setpoint from 8°C to 12°C cut measured minibar energy by ~15% over 30 days (weather‑normalized). Method: utility submetering on a 12‑room sample and nightly interior temp logs (8 bottles, restocked daily). No brand names disclosed; cabinet geometry verified against vendor manuals.

Sustainability & ROI: The 2026 Procurement Perspective

In 2026, hotel procurement is no longer just about the initial invoice. It’s about ESG compliance and Total Cost of Ownership (TCO). When selecting a hotel mini fridge, smart buyers look at the 5-year financial trajectory, not just the unit price.

Green Compliance: Refrigerants and Energy Standards

The shift toward eco-friendly hospitality is accelerating. Most modern compact units now utilize R600a (Isobutane), a low-GWP (Global Warming Potential) refrigerant.

-

Pro Tip: Ensure your maintenance team is trained on R600a protocols. While it’s the gold standard for efficiency, it requires specific handling compared to older refrigerants.

-

Energy Metrics: Don’t just look for an “Energy Star” sticker. For a high-occupancy resort, verify the specific kWh/24h rating on the datasheet. In our experience, a unit that saves just 0.1 kWh per day can save a 300-room hotel thousands of dollars in annual energy costs.

The “Total Cost of Ownership” (TCO) Reality

We often see procurement teams fall into the “cheapest unit trap.” To see the real cost, you must use this formula:

TCO = Purchase Price + Installation + Energy Costs (5 Years) + Maintenance – Resale/Scrap Value.

If poor ventilation (as discussed above) reduces a fridge’s lifespan from 7 years to 2 years, the “budget” unit becomes the most expensive mistake in your FF&E budget. Investing in a professional-grade hotel minibar refrigerator with a robust duty cycle and high-efficiency cooling is a hedge against future inflation and replacement labor costs.

Aligning with Global Sustainability Roadmaps

Major hospitality brands are now aligning their procurement with the American Hotel & Lodging Association (AHLA) sustainability pillars. By choosing energy-efficient appliances, you aren’t just saving on utility bills; you are future-proofing your property for upcoming “Green Key” or LEED certifications.

Moon’s Procurement Insight: Many designers set minibars to 4°C (40°F), which is unnecessary for beverages and doubles energy use. For most guestroom applications, a setpoint of 8°C to 12°C (46°F – 54°F) provides the perfect “chilled” experience while significantly extending the compressor or absorption unit’s life.

Frequently Asked Questions (FAQ)

Q: Can I use a standard home mini fridge in a hotel room?

A: You can, but it’s risky. Consumer compact fridges are often noisier (mid‑30s to low‑40s dB) and lack detailed built‑in ventilation instructions that hospitality vendors provide. Manufacturer documents for hotel minibars explicitly warn that blocked or undersized vents can cause overheating and void warranties. See the Minibar Systems ventilation specification for a representative example of required openings and warnings (link above).

Q: What’s the ideal temperature setting for a hotel minibar?

A: For beverages, 8–14°C suits most properties. Where efficiency is critical, many EU testing contexts use ~12°C “Cellar” as a balanced point; manuals note that higher set points reduce energy use. Confirm capabilities and ranges in your model’s user/installation manual.

Q: How often do silent absorption fridges need maintenance?

A: The sealed circuit is maintenance‑free, but you should clear dust from the absorber area and ventilation path at least annually and keep grills unobstructed. Dometic’s hotel minibar manuals recommend periodic cleaning and unobstructed airflow to maintain performance (see Dometic installation manual link above for representative guidance).

Professional Procurement Checklist

- Noise level at 1 m (note mode): target ≤30–33 dB for compressor units in premium suites; 0dB for absorption where feasible.

- Technology and climate fit: absorption vs compressor vs thermoelectric; documented cooling performance at 25–32°C ambient.

- Ventilation requirements: minimum free‑area per opening (aim 200cm² baseline unless manual specifies more), duct path, and clearances; warranty language if unmet.

- Energy data: kWh/24h and kWh/year; Energy Star or EN 16825 applicability (verify per model); planned set point (e.g., ~12°C) and stabilization time after restock.

- Refrigerant: R600a or other; disposal and safety notes as per facilities SOP.

- Integration: door‑on‑door or sliding hinges; reversible door; max panel thickness/weight; cabinet envelope including power plug and rear duct width.

- Features and durability: auto‑defrost, LED lighting, adjustable shelving, lock option, spare parts availability, warranty terms, and covered failure modes.

Wrapping up A high‑performance hotel mini fridge is quiet, stable, and serviceable. You get there by choosing the right technology for the room and climate, and by engineering the cabinet so the unit can breathe. Don’t let a minor cooling issue become a major guest complaint. For cabinet drawings, grille sizing reviews, or wholesale sourcing support, get a free cabinetry compatibility consultation and a wholesale quote from DERBAL. If you’re exploring models and specs, you can also browse the current DERBAL catalogue.