Luxury rates buy more than views. Guests are paying for confidence—confidence that your spa is clean, safe, and engineered to standards that justify premium pricing. Chlorine wipes and logbooks help, but they don’t change the biology of your surfaces. The material itself either passively suppresses microbes between cleanings—or it doesn’t. That’s why a growing number of 5‑star resorts are specifying uncoated copper spa basins and fittings as part of their antimicrobial spa equipment standard.

Key takeaways

- Hygiene is a brand asset: visible, evidence-backed materials like uncoated copper support premium pricing by signaling trust.

- EPA protocols allow copper surfaces to claim continuous antibacterial reduction (≥99.9% in about an hour) when uncoated and maintained, with residual antiviral activity expectations within two hours under specific registrations .

- TCO improves in high-traffic spas: fewer replacements, lower biofilm remediation, and simplified professional foot soak basin hygiene workflows.

- In coastal resorts like the Maldives, copper basins with copper‑nickel drains resist salt‑air corrosion and fit island logistics realities (longer service life, fewer emergency shipments).

- Chemicals are necessary but transient; substrate choice sets your passive bioburden baseline between cleanings.

The science of hygiene: copper antimicrobial efficacy in hotels

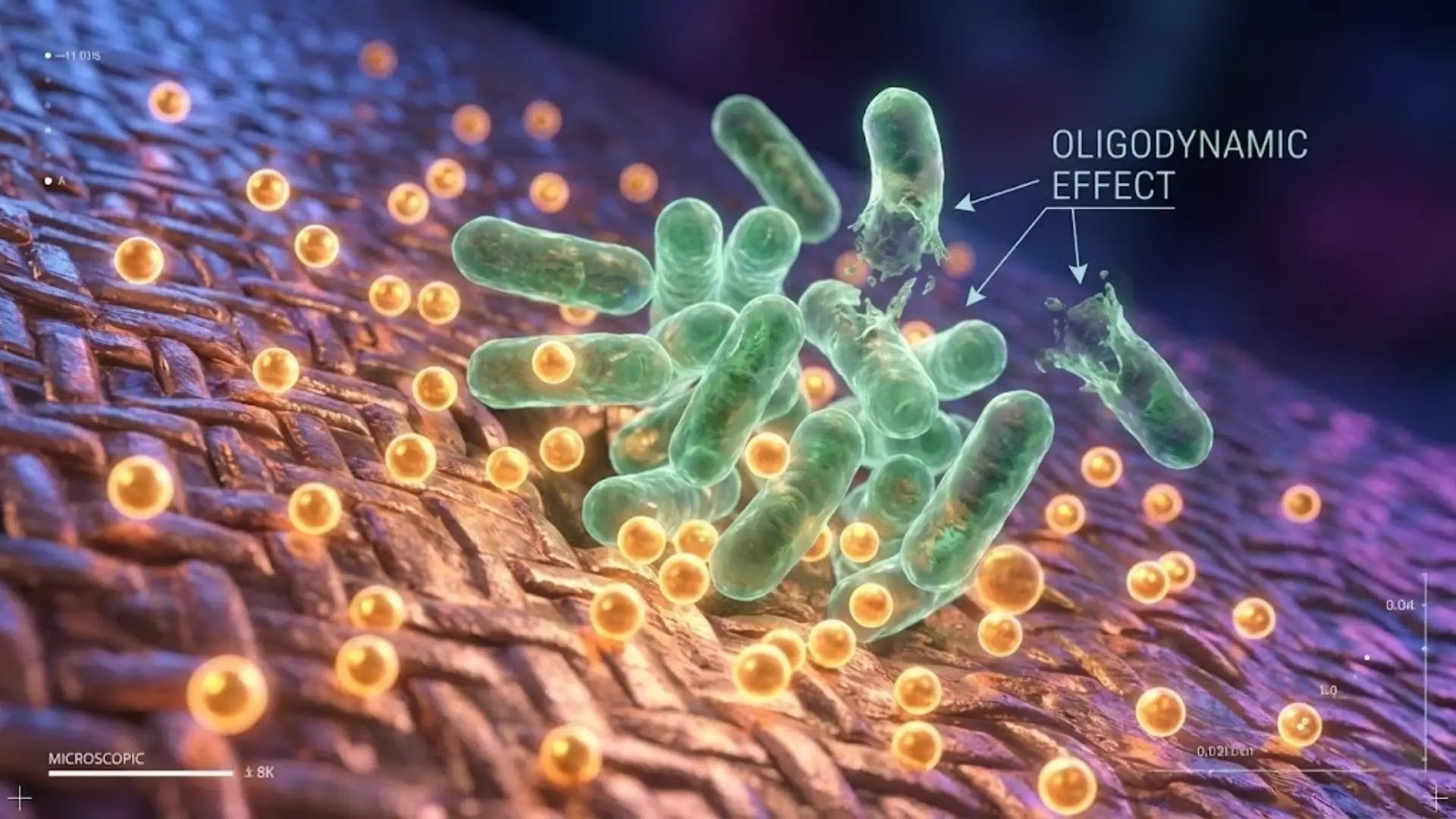

Copper’s effectiveness isn’t folklore; it’s materials science. Through the oligodynamic effect, copper releases Cu+/Cu2+ ions that disrupt microbial membranes, generate reactive oxygen species, denature proteins, and damage DNA/RNA—leading to rapid “contact killing.” Peer‑reviewed reviews summarize these mechanisms and their implications for high‑touch environments in hospitality and healthcare, including biofilm pressure reduction on wet surfaces.

Regulatory context matters for procurement. Under the U.S. framework for hard, non‑porous copper and copper‑alloy surfaces, EPA test protocols support “continuous reduction of bacteria” claims, targeting at least a 3‑log (≥99.9%) reduction within roughly one hour on treated carriers compared with stainless steel controls. Certain high‑copper alloys (≥95.6% Cu) also hold residual antiviral registrations with expected inactivation within two hours—while clearly remaining a supplement to, not a replacement for, routine cleaning and disinfection . Surfaces must be uncoated—no waxes, lacquers, or varnishes—or antimicrobial function is blocked.

Copper sits under two hours; stainless steel and common plastics extend into days under typical environmental conditions reported in the literature. Kinetics vary by species, humidity, and load, but the directional contrast is robust across studies. In spa contexts where basins are wet, copper’s kill rate is slower than on dry touch plates; still, ion release lowers biofilm pressure versus inert substrates, assisting compliance and faster, more predictable turnovers—an important lever for hotel wellness equipment sanitization.

Operational benefits and TCO drivers for antimicrobial spa equipment

When you measure what matters—downtime, labor minutes between treatments, incident risk—uncoated copper basins and copper‑nickel (Cu‑Ni) drains can shift total cost of ownership in your favor.

- Professional foot soak basin hygiene: Lower between‑client bioburden reduces the risk of stubborn biofilms that force deep cleans and service delays. Industry regulations in cosmetology, used here as an analogue, highlight how labor‑intensive basin disinfection can be when materials harbor biofilms—especially in plastics with scratches and complex hydraulics (see California Board of Barbering and Cosmetology cleaning mandates for footbaths). Copper doesn’t remove the need to disinfect; it provides a passive biological baseline that helps keep loads in check.

- Fewer replacements, less surprise downtime: Plastics scratch and craze; sealed hardwoods swell and delaminate; both drive hygiene complaints and unplanned replacements. Marine‑proven copper alloys and Cu‑Ni drains deliver longer service life when commissioned and maintained correctly.

- Simplified, repeatable sanitization: Smooth, uncoated copper geometries without unnecessary crevices minimize traps. Staff follow the same EPA‑registered cleaners, but with materials that fight back between cycles—helpful for predictable turnover windows.

Material performance comparison for high‑traffic spa environments

| Material | Antimicrobial speed | Durability (coastal/wet) | Maintenance cost/complexity |

|---|---|---|---|

| Copper (uncoated high‑Cu alloys) | ≥99.9% bacterial reduction in ~1 hour under EPA protocol; many organisms inactivate within minutes–hours in literature; residual antiviral expectations ≤2 hours on ≥95.6% Cu alloys | Excellent salt‑air resistance; Cu‑Ni drains resist seawater corrosion and biofouling; avoid sulfide‑polluted stagnation; manage galvanic pairing | Routine cleaning still required; absolutely no coatings; passive baseline can reduce biofilm pressure and labor spikes |

| Stainless steel (304/316) | No intrinsic antimicrobial effect; survival days–weeks observed in studies | High structural durability; tea‑staining/pitting possible in salt air; neutral biology | Thorough disinfection burden persists; scratches harbor biofilm; similar labor to plastic |

| Plastic (HDPE/acrylic) | No intrinsic antimicrobial effect; survival days–weeks; scratches increase risk | Low capex; prone to scratching/UV aging; deformation risk | Intensive disinfection; higher replacement probability; downtime risk |

| Wood (sealed hardwoods) | No intrinsic antimicrobial effect; porosity retains moisture | Aesthetic but poor fit for wet high‑traffic basins; swelling/warping | High maintenance; refinishing/replacements; hygiene non‑compliance exposure |

Evidence anchors: U.S. EPA copper/copper-alloy surface protocol; NCBI review on copper mechanisms; copper.org marine/corrosion guidance.

Maldives case perspective: luxury resort spa engineering solutions

Remote islands add two unforgiving variables to spa engineering: salt air and logistics. In the Maldives, salt‑laden humidity accelerates corrosion on fittings and drains, and resupply cycles are long. That’s where material selection and planning pay off.

- Alloys that last: Uncoated high‑copper basins paired with C70600 (90‑10) or C71500 (70‑30) Cu‑Ni drains and traps form protective oxide films in clean, aerated seawater and resist biofouling—documented in marine applications. Manage galvanic couples and avoid sulfide‑polluted stagnation to keep rates low .

- Commissioning and care: Bring systems online in clean water to form films, maintain adequate flow, and use compatible disinfectants. Never coat copper; coatings block ion release and negate antimicrobial function.

- Logistics and spares: Consolidate shipments, pre‑clear customs, and carry spare drain kits and gaskets to avoid airfreighting parts mid‑season. Sequence installation to keep treatment rooms online..

Neutral micro‑example (Maldives workflow): In a recent island‑resort specification, the engineering package consolidated uncoated copper foot‑soak basins with Cu‑Ni drain assemblies, matched fittings to avoid galvanic mismatches, and staged delivery to align with a two‑week shutdown. The result wasn’t “magic”—just fewer corrosion surprises, cleaner baselines between disinfectant cycles, and no emergency airfreight.

Copper vs plastic spa bowls: choosing for brand and compliance

If your narrative is “hygiene as luxury,” plastics and wood work against you. Scratches in plastic accumulate biofilm, demanding harsher chemicals and longer dwell times. Sealed hardwoods look artisanal but absorb moisture and degrade, raising complaint risk. Stainless steel is durable and neutral but offers no passive microbial reduction. Copper sets a lower baseline bioburden between treatments—especially valuable for professional foot soak basin hygiene—while still accepting standard sanitizers. Here’s the deal: chemicals reset the clock; copper slows it down between resets.

One‑stop advantage: design, drainage, and logistics in one specification

To realize copper’s benefits, specify the system—not just the bowl:

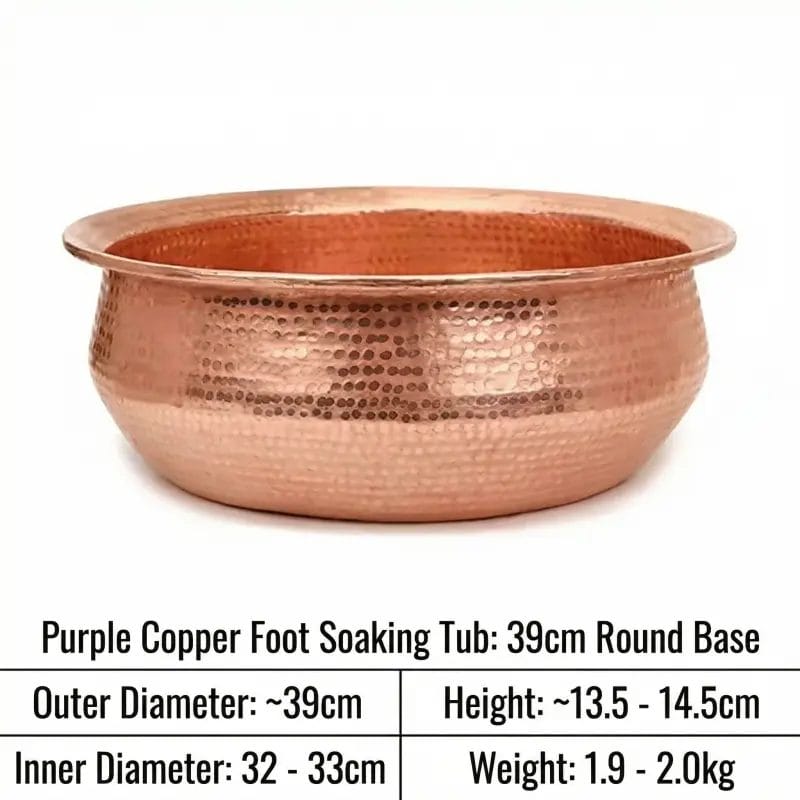

- Geometry and finish: Smooth, accessible radii; no blind crevices; uncoated high‑copper alloy. Shot‑peened or lightly textured finishes can increase ion release while remaining cleanable.

- Drainage engineering: Cu‑Ni drain/trap kits; galvanic isolation from more noble metals; adequate slope and flow; venting to prevent stagnant pockets.

- Commissioning and care: Form protective films in clean water; routine cleaning with compatible agents; never apply wax/lacquer/varnish.

- Logistics plan: Consolidate island deliveries; include spares; schedule install windows to protect revenue days.

FAQ: procurement questions answered

1.What does “EPA‑registered antimicrobial copper” actually mean for a spa basin?

For indoor hard, non‑porous uncoated copper/copper‑alloy surfaces, EPA protocols support claims of continuous antibacterial reduction (e.g., ≥99.9% in about one hour) and certain residual antiviral expectations within two hours for specific high‑copper alloys. It never replaces routine cleaning and disinfection; it supplements them under labeled conditions. See the EPA’s protocol linked above.

2.Does copper replace chemical disinfection?

No. Copper provides a passive, continuous reduction baseline between disinfection cycles. You still clean and disinfect per SOPs and local regulations. Copper simply helps keep loads lower between cycles.

3.How does copper perform in wet spa basins compared with dry touch plates?

Kill rates are slower in submerged/wet conditions, but ion release measurably disrupts biofilms over time. Proper surface finish and water chemistry increase effectiveness. In practice, you see fewer persistent biofilm events and more predictable turnovers versus inert materials.

4.Which alloys or components are recommended for coastal resorts?

Uncoated high‑copper basins plus C70600/C71500 copper‑nickel drains and fittings. Avoid galvanic mismatches, commission in clean water to form protective films, and maintain adequate flows.

5.Are there downsides to copper?

Higher capex versus plastics, and patina development over time (which many luxury brands view as aesthetic). The surface must remain uncoated to function; abrasive over‑polishing can alter appearance. Training and SOP updates are required—straightforward but essential.

Elevate your wellness engineering with the global leader in resort supplies. Whether you are retrofitting an urban tower or developing a Maldives retreat, DERBAL delivers the antimicrobial spa equipment your brand deserves.